It's been a busy week here at the shop 3D printing rather large parts for my fusion drive spaceship project. This has also been a good test of my new Creality CR-10 S4 3D printer. I am learning new things making this project and getting to know the ins and outs of the new printer so it's all good.

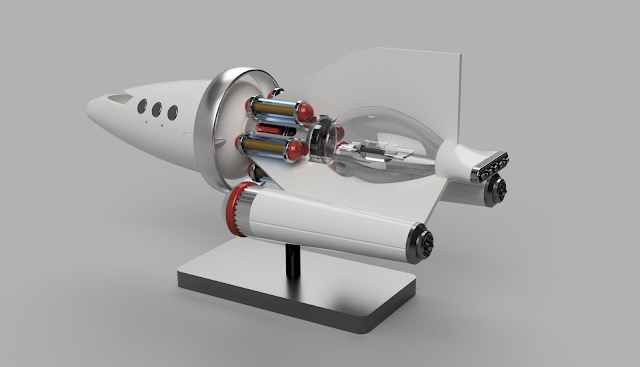

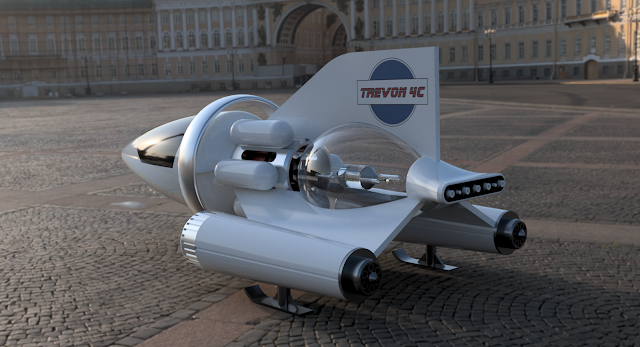

This is the final design of the model spaceship. I still have not figured out a good name for the ship so if any of you have any suggestions I would be more than happy to hear from you. The model when completed will be over 2 feet long so it is a BIG model to say the least. With that in mind here are some of the components that I have already 3D printed.

These front assemblies took a little time to work out but the effect will look very good on the finished model. In the image above you can see a clear dome on the right. This dome is just half of a Christmas ornament that I had found at a craft store while shopping for parts some time back. Next is the mounting ring that the dome fits into and then the ring is mounted to the front of the engine assembly as shown in it's completed form on the left. I will have to do some sanding and painting of course to match the computer model but I see no real difficulty in getting these assemblies the way I want them to be.

Next came the ring that wraps around the mid-section of the spaceship. This part printed very well and as you can see in the photo of me holding it, it's a pretty big part. I will have to do a little prep work on the part to smooth it out but overall it is already in very good shape. It should look really good once I have it smoothed and painted silver for the project.

In this series of parts I 3D printed the components that make up the exhaust assemblies of the spaceship. Again smoothing of the 3D printed parts will be needed to get them in shape but from the looks of it this will not be an issue to get them ready for painting once again.

Here are the components that make up the mount for the fusion drive (light bulb). The top photo shows where the mount is located without the fuel canisters added so that you can see exactly where this assembly goes. In the photo just below it on the left is the actual metal mount for the light bulb which will be the fusion drive for the spaceship. In the center is the housing for the metal mount and on the left is the outer mount for the fusion canisters that will be added later on in the build.

Here the metal mount is assembled into it's housing

Once the bulb mount is assembled then it is inserted into the outer housing for the fuel canisters.

Here is another shot of the model with the fuel canisters mounted to the mid-section of the model. I still have some work to do on the canisters to get them ready for photos so I will hold off until the next installment of this project to show you how all six of the canisters are put together.

So far with the 3D printing of the parts that I have just shown you it has taken me 58 hours to do the 3D printing. The largest and last piece I plan on 3D printing is the front capsule where all the windows are mounted in the model. From what my 3D printing software tells me this part alone will take 18 hours to 3D print. Not sure I want to spend my entire waking day watching this part print or let it run through the night and hope for the best. I will just have to see once I get to that point. As I am writing this I am 3D printing one of the large white mid-sections for one of the side engines. Again this should take around seven hours or so to complete. Not to bad as I got an early start on it this morning so before the afternoon is done the part will be also. So it will be a good day.

Stay tuned for further updates on this project as it should be a pretty impressive build once I get all the parts 3D printed, painted and assembled into this big model.